HDPE Pipes and Fittings

HDPE pipes and fittings are made from high-density polyethylene material and are commonly used in various applications such as water supply, gas distribution, wastewater and stormwater drainage, irrigation, electrical and telecommunication sectors due to their durability, flexibility, and corrosion resistance.

Advantages for using HDPE Pipe: Light-weight for ease of installation and handling. Immunity to corrosion, chemical and micro-biological resistance. Flexible. High impact strength and toughness. Alternative installation techniques possible.

Size available: OD20mm – OD1000mm, PN10 & PN12.5.

01. HDPE Corrugated Subsoil Drainage Pipes

HDPE Corrugated Subsoil Drainage Pipes are a type of HDPE pipe with corrugated walls designed for efficient drainage of water from the soil. Mainly used for subsoil drainage for playing fields, golf courses, stadium, roads, highway and construction works to drain off excess ground water. It is available in single and double wall. It is also available with full perforation or part perforation for subsoil drainage system. Sizes available: 100mm dia. – 600mm dia.

HDPE Double Wall Corrugated Sewer and Drainage Pipes

HDPE Double Wall Corrugated Sewer and Drainage Pipes Mainly used for gravity and low pressure sewerage and drainage such as waste water, sanitary sewer and storm sewerage for municipal or industrial use. Lightweight, Flexible, Easy Installation, Chemical and Abrasion Resistant, Hydraulic Efficiency & Tough Structural Performance.

Size available: ID100mm – ID600mm

02. PVC, uPVC, and mPVC pipes

PVC, uPVC, and mPVC pipes are made from different types of polyvinyl chloride materials and are widely used in water supply, irrigation, and drainage systems due to their lightweight, cost-effectiveness, and chemical resistance.

Size available: 1/2″ (15mm) – 18″ (450mm).

03. ABS Pipes

ABS (Acrylonitrile butadiene styrene) Pipes are made from a thermoplastic polymer and are commonly used in drainage and sewer systems due to their high impact resistance and durability.

Size available: 1/2” (15mm) – 6” (150mm).

04. PPR Pipes

PVC, uPVC, and mPVC pipes are made from different types of polyvinyl chloride materials and are widely used in water supply, irrigation, and drainage systems due to their lightweight, cost-effectiveness, and chemical resistance.

Size available: 1/2″ (15mm) – 18″ (450mm).

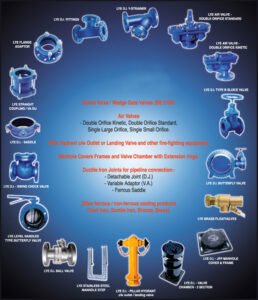

05. Ductile Iron Pipes and Fittings

Ductile Iron Pipes and Fittings are made from ductile cast iron and are known for their high strength and durability, making them suitable for water distribution systems.

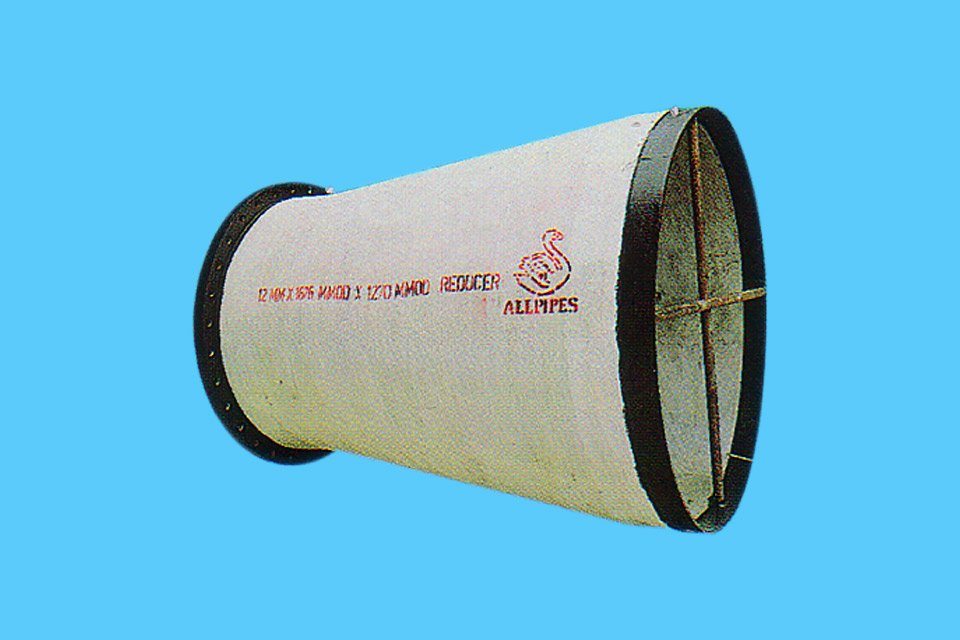

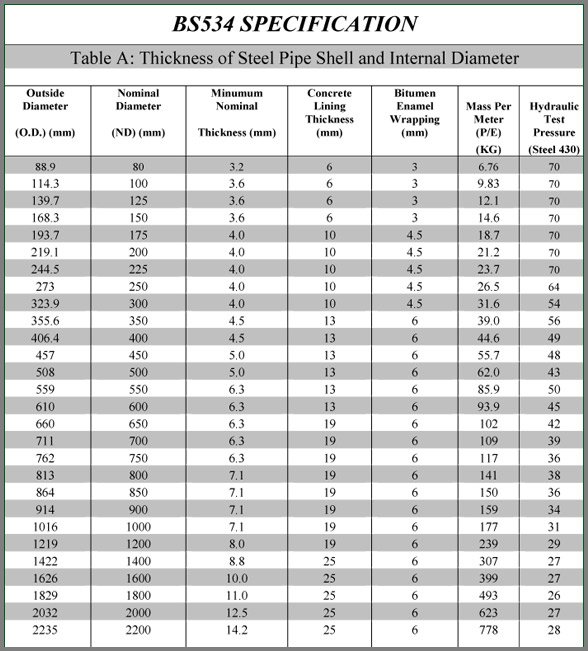

06.Mild Steel Cement Lined Pipes and Fittings

Mild Steel Cement Lined Pipes and Fittings are made from mild steel pipes coated with cement lining to provide corrosion resistance, making them suitable for water supply and sewage systems.

07. Stainless Steel Pipes & Fittings

Stainless Steel Pipes and Fittings are made from stainless steel, known for their corrosion resistance and durability, making them suitable for various applications including water supply, gas distribution, and industrial processes.

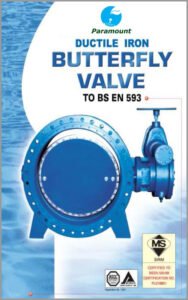

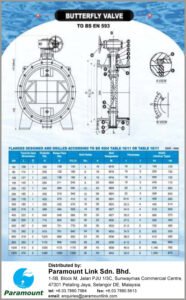

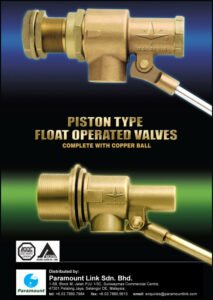

08. Valve

Features of HDPE Pipes and Fittings

HDPE pipes and fittings are commonly used in various applications due to their unique properties and benefits. Some of the key uses and special features of HDPE pipes and fittings include:

- Water Supply: HDPE pipes are widely used for water distribution systems in residential, commercial, and industrial settings due to their resistance to corrosion, chemicals, and abrasion. They are also lightweight, flexible, and easy to install.

- Gas Distribution: HDPE pipes are commonly used for natural gas distribution systems due to their leak-proof joints, high resistance to chemicals, and low permeability to gases.

- Drainage Systems: HDPE pipes are suitable for drainage systems, including stormwater management, culverts, and subsoil drainage, due to their smooth interior surface that prevents clogging and their ability to withstand heavy loads.

- Agricultural Applications: HDPE pipes are used in irrigation systems, agricultural water supply, and land drainage due to their durability, UV resistance, and ability to withstand harsh environmental conditions.

- Mining and Industrial Applications: HDPE pipes are used in mining operations, industrial processing, and chemical transport due to their high impact strength, resistance to abrasion, and long service life.

Special Features of HDPE Pipes and Fittings:

- High-Density Polyethylene Material: HDPE pipes and fittings are made from a durable and flexible material that offers high strength, toughness, and resistance to chemicals and abrasion.

- Corrosion Resistance: HDPE pipes are resistant to corrosion, rust, and chemical degradation, making them suitable for various applications where other materials may fail.

- Lightweight and Flexible: HDPE pipes are lightweight and flexible, which facilitates easy handling, transportation, and installation, reducing labor and equipment costs.

- Leak-Free Joints: HDPE pipes can be joined using heat fusion techniques, creating seamless and leak-proof joints that ensure long-term reliability and performance.

- Long Service Life: HDPE pipes have a long service life of up to 50 years or more, reducing maintenance and replacement costs over time.

- Environmentally Friendly: HDPE pipes are recyclable and environmentally friendly, making them a sustainable choice for infrastructure projects.

Overall, the special features of HDPE pipes and fittings make them a versatile and cost-effective solution for various piping applications across different industries.